Plastic Extrusions: Comprehending the Types, Utilizes, and Advantages of Plastic Extrusions

Are you interested concerning plastic extrusions? Do you wish to comprehend the various types, utilizes, and also advantages of this functional production procedure? Look no more!

In this article, we will certainly explore the world of plastic extrusions, supplying you with beneficial insights and also information. Whether you are a DIY lover or an expert in the industry, this write-up will assist you make educated decisions when it pertains to choosing and utilizing plastic extrusions.

So, allow's dive in and discover the countless opportunities of this ingenious innovation!

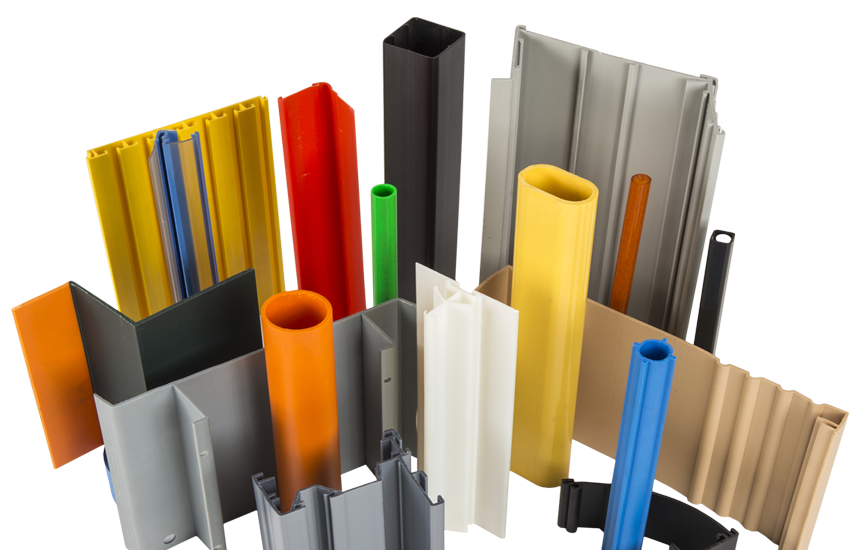

The Various Types of Plastic Extrusions

There are numerous types of plastic extrusions that are utilized in different markets.

One kind is called account extrusion, which is commonly used to develop intricate shapes such as tubing, poles, as well as networks. It includes pressing liquified plastic via a die that has actually the wanted form.

One more kind is sheet extrusion, which is utilized to produce level plastic sheets of different densities. This process includes melting plastic pellets and after that squeezing the molten plastic via a narrow gap to develop a continual sheet.

Movie extrusion is another type, which is used to generate slim plastic films for product packaging and also other applications. In this procedure, the plastic is thawed and after that extended to accomplish the preferred density.

There is coextrusion, which entails combining several layers of various plastics to create a single extruded item. This technique is usually utilized to boost the homes of the end product, such as boosting or adding a protective layer barrier properties.

Understanding the various sorts of plastic extrusions can help you select the most suitable option for your certain industry as well as application.

Discovering the Different Uses Plastic Extrusions

Among the several ways plastic extrusions are made use of remains in the building market. They supply a vast array of applications and also advantages that make them an ideal option for various building tasks.

Plastic extrusions are used in the building of doors and windows, where they give superb thermal insulation and also toughness. They are additionally made use of in the construction of structural parts such as beam of lights, columns, as well as roof.

Plastic extrusions are lightweight, yet strong and flexible, making them simple to set up and take care of. They can be customized to fit details demands, allowing for higher layout flexibility. Whether it's for domestic, industrial, or industrial building and construction, plastic extrusions are a cost-efficient service that offers durable performance.

Another common usage of plastic extrusions in the building industry remains in the installation of electric systems. They are used for cord administration, supplying a organized as well as cool service for transmitting and protecting electric cables. Plastic extrusions are also resistant to corrosion, dampness, and UV rays, making them appropriate for exterior applications such as fences, barriers, as well as decking.

Along with their functional uses, plastic extrusions can also improve the visual appeals of a building. They are offered in a selection of surfaces and also shades, enabling imaginative and visually appealing styles. Whether it's for ornamental or functional objectives, plastic extrusions are a versatile remedy that is widely utilized in the construction industry.

Advantages and also Benefits of Plastic Extrusions

The advantages and also advantages of plastic extrusions make them a cost-effective and also versatile option for a large range redirected here of construction jobs. You are choosing for a light-weight material that is simple to install as well as manage when you select plastic extrusions. The versatility of plastic extrusions enables them to be molded right into numerous shapes and also sizes, making it much easier to customize them to fit your certain project demands.

Plastic extrusions also supply excellent durability and also resistance to weather, chemicals, and UV rays. This makes them extremely appropriate for outside applications, such as windows, doors, and roof. Furthermore, plastic extrusions are non-corrosive, which suggests they won't corrosion or degrade gradually, guaranteeing durable performance.

One more advantage of plastic extrusions is their cost-effectiveness. Contrasted to various other materials like steel or timber, plastic extrusions are usually a lot more economical. They require minimal maintenance and also have a longer life expectancy, reducing the need for frequent replacements or fixings.

Plastic extrusions are extremely lasting. Lots of are made from recycled products, making them an ecologically friendly selection. They are likewise recyclable themselves, adding to a circular economy

Aspects to Take Into Consideration When Picking Plastic Extrusions

When taking into consideration which plastic extrusions to choose for your project, you ought to consider elements such as the specific requirements of your application, the desired sizes and shape, and also the compatibility with other materials.

Each project has its very own one-of-a-kind requirements, so it is essential to meticulously examine these elements prior to choosing.

Think about the setting in which the extrusions will certainly be utilized. Recognizing these requirements will assist you pick the suitable plastic material and also manufacturing procedure.

Next, think of the preferred form and size of the extrusions. Plastic extrusions can be customized to satisfy your specific specifications. Whether you require a complex style or a straightforward account, make certain to interact your requirements to the maker.

Consider the compatibility of the plastic extrusions with other materials. Make sure that they can function with each other effortlessly if your task entails joining the extrusions with other elements. Compatibility is critical for the general functionality and also longevity of your job.

Ingenious Applications and also Future Fads in Plastic Extrusions

It's crucial to explore the innovative applications as well as future patterns in plastic extrusions if you're looking to remain ahead in the sector.

Plastic extrusions have actually come a lengthy way and also are now being made use of in various markets for a large visit this page range of applications. - extrusion of plastics

Among the innovative applications of plastic extrusions is in the vehicle market. Plastic extrusions are being made use of to produce aerodynamic and light-weight components for cars, such as bumpers, body panels, as well as useful source interior trims. This not only assists in lowering the overall weight of the car however likewise boosts gas effectiveness.

An additional cutting-edge application remains in the construction industry. Plastic extrusions are being used to create weather-resistant and also durable profiles for windows, doors, and roof systems. These accounts are not just affordable yet also use superb thermal insulation buildings.

When it comes to future fads, there is an expanding demand for sustainable products in different industries. Plastic extrusions made from recycled materials or naturally degradable polymers are getting appeal as they supply environmental advantages.

Additionally, developments in modern technology are enabling more complicated as well as detailed layouts to be developed making use of plastic extrusions, opening up new opportunities in product growth.

Final thought

So now you understand the different sorts of plastic extrusions, their uses, and the benefits they offer.

With this knowledge, you can make enlightened decisions when picking the right plastic extrusions for your needs.

Whether you're trying to find profiles, tubing, or personalized shapes, plastic extrusions supply toughness, cost-effectiveness, as well as flexibility.

Keep in mind the factors reviewed and also remain upgraded on the most recent technologies in the field.

Welcome the future trends as well as discover the limitless possibilities that plastic extrusions have to provide.

Another common use of plastic extrusions in the building and construction sector is in the installment of electric systems. In addition to their functional usages, plastic extrusions can also enhance the aesthetics of a structure. Whether it's for functional or ornamental purposes, plastic extrusions are a functional option that is commonly used in the construction industry.

Plastic extrusions are being made use of to create lightweight and also wind resistant components for vehicles, such as bumpers, body panels, and also interior trims. Plastic extrusions are being utilized to produce long lasting and weather-resistant profiles for home windows, doors, as well as roofing systems.